Navigating New Recycled Content Regulations for Food Packaging

As the push for sustainability gains major traction, recycled content regulations for food packaging are becoming more common. The United States, Canada, and regions within the European Union are developing new laws that will soon require food manufacturers to incorporate recycled materials into their packaging. Some of these laws have ambitious targets, like 50% recycled content in plastic beverage containers in California, with just a few years to make it happen.

These new regulations create an immediate need for food manufacturers to adapt their packaging strategies to match new demands. Here’s a look at these evolving regulations and the actionable steps you can take to stay compliant.

What are the latest recycled packaging regulations?

Countries worldwide are enacting recycled content laws aimed at reducing environmental impact and promoting a circular economy. These are some of the prominent initiatives food safety manufacturers need to prepare for:

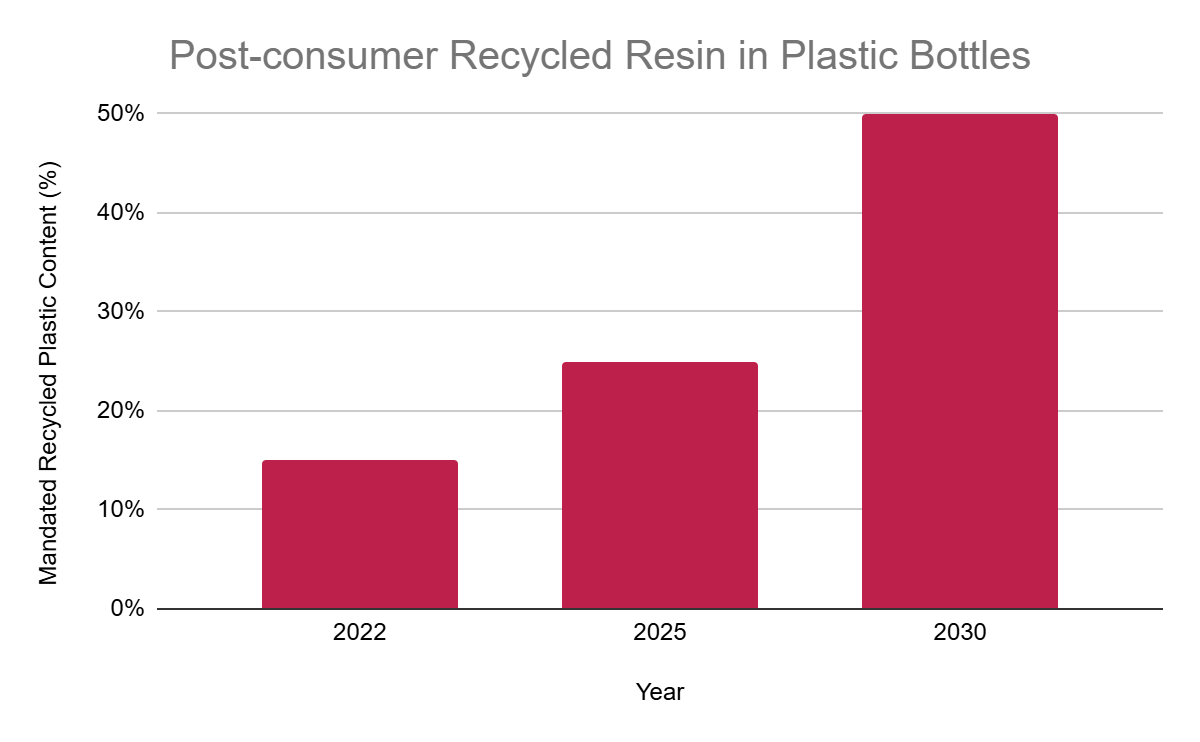

- United States: California Assembly Bill 793 currently mandates that 15% of beverage containers have recycled plastic content. This will increase to 25% by 2025 and 50% by 2030, with states like Maine, Oregon, Colorado, and Minnesota already following suit.

- Canada: Proposed legislation in Canada aims to increase the recycled content in plastic packaging and reduce single-use plastics overall across the next decade.

- European Union: The European Packaging and Packaging Waste Regulation (PPWR) will mandate minimum recycled content levels in packaging across its member states with a 2030 target timeline.

These mandates are only the beginning, highlighting a global shift that food manufacturers must adapt to quickly.

Challenges of Using Recycled Food Packaging Materials

While necessary to continue production into the near future, switching to recycled packaging is no easy feat for food manufacturers. Making these materials viable for use can be difficult, and in some instances, they may even pose potential health risks for consumers. Manufacturers could face the following challenges in their pursuit to meet new regulations.

- Ensuring food safety: Recycled packaging can harbor hazardous chemicals from prior uses, potentially jeopardizing consumer health.

- Maintaining product integrity and shelf life: Recycled materials may not provide the same level of protection as virgin materials, impacting product quality, longevity, and stability.

- Meeting stringent compliance requirements: Packaging regulations require enhanced tracking and reporting. Take, for example, California’s requirement for beverage manufacturers to disclose recycled plastic usage by resin type.

- Navigating consumer perception: Recycling terms such as “recyclable” or “compostable” can create confusion for consumers.

- Using legal terminology: Clear labeling and compliance with state/local laws (such as those defined by the FTC) are essential.

Food manufacturers not only face a tremendous overhaul of their operations but also a narrowing timeline. Failing to act quickly could lead to a breach of public health, a loss of consumer trust, and costly legal repercussions.

How to Implement Recycled Content Packaging While Maintaining Safety

Meeting new recycled content requirements while continuing to prioritize food safety will be a delicate balancing act. The manufacturers that succeed will likely rely on a combination of the following strategies:

Vetting Packaging Suppliers with Strong Food Safety Records

Choosing suppliers who demonstrate compliance with food safety standards is key to preventing contamination and mitigating risks. Look for suppliers with proven histories of safely handling recycled materials and that are transparent about their recycling processes and testing standards.

Integrating VACCP Processes to Manage Risks

Apply a Vulnerability Assessment and Critical Control Points (VACCP) strategy to identify and control risks related to recycled content. VACCP can help detect weak points in your supply chain, protecting against fraud and contamination in recycled packaging.

Consider enrolling in AIB International’s Food Fraud Online course to build your VACCP knowledge and strengthen your defense.

Ensuring Robust Testing Procedures and Audits

Recycled materials require regular testing to comply with food safety and environmental regulations. Just because your packaging met the requirements once doesn’t mean it always will. Trust, but verify. Set up rigorous testing schedules for your packaging to monitor contaminants and ensure safety.

Conducting periodic audits of your suppliers and materials can help you verify ongoing compliance. Use services like AIB International’s Assign an Expert to outsource what can be a complicated process.