Food Manufacturers Cause 600 Million WHAT Each Year?

The World Health Organization (WHO) estimates that there are 600 million cases of foodborne illness globally, and 420,000 people die from foodborne disease each year. Children under the age of five account for approximately 30 percent of those foodborne deaths (WHO). Beyond that, the impacts on personal finances due to lost wages and medical bills can be catastrophic for consumers.

The World Health Organization (WHO) estimates that there are 600 million cases of foodborne illness globally, and 420,000 people die from foodborne disease each year. Children under the age of five account for approximately 30 percent of those foodborne deaths (WHO). Beyond that, the impacts on personal finances due to lost wages and medical bills can be catastrophic for consumers.

Watch Webinar Download Slides Seminar Registration

According to the FDA, the number of food/cosmetic products recalled in the U.S. each year has been in decline, peaking at 3,609 in 2017, but then dropping to 1,536 in 2020 and only 620 as of May 25 this year (FDA). Though these figures are encouraging, why do foodborne illnesses continue to persist? In part, because ensuring food safety can be very difficult and takes a proactive approach by food manufacturers and processors.

Recall Drivers

There are any number of variables that may prompt recalls, but a few key drivers include:

- Consumer demands are driving increased imports around the world. Preferences for products like fruits, vegetables and seafood are driving increased imports, which can increase the distance some foods must travel to reach their market.

- The growing complexity of the supply chain means that ingredient sourcing, production, packaging, and distribution can involve numerous steps and across many countries with varying regulations.

- Countries and local governments have improved detection and recognition of food safety problems.

- There is better reporting by manufacturers, such as the Reportable Food Registry in the U.S., which provides information about recalls.

FAT TOM, Who?

Despite the challenges presented by these many variables, it is microbes – bacteria, yeasts, and mold – that are most often responsible for foodborne illnesses. The conditions affecting microbial growth can be succinctly summarized with the simple acronym: FAT TOM.

- Food

- Acidity (growth requires a pH greater than 4.6)

- Time

- Temperature (40* F to 140* F/4.4* C to 60* C)

- Oxygen (aerobic/anaerobic)

- Moisture/Water Activity (pathogen growth at Aw greater than 0.86)

Prevention is Key

Sec. 402(a)(4) of the FDA’s Federal Food, Drug, and Cosmetic Act states that “A food is illegal if it has been prepared, packed, or held under insanitary conditions whereby it may have been rendered injurious to health.” This places the emphasis on prevention by managing sanitary conditions and focuses on the potential for producing violative product in unsanitary conditions, which could prompt harborage, accumulation of debris, microbiological issues, and otherwise.

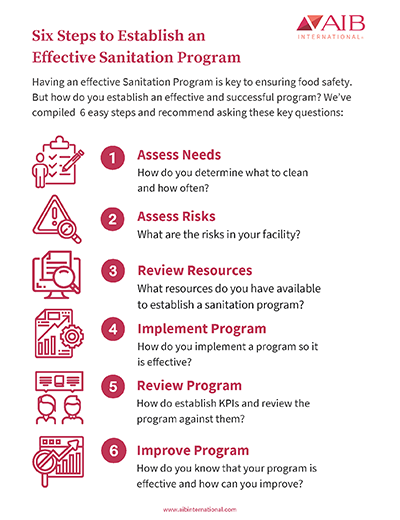

To prevent these conditions, every food manufacturing and processing facility must have a proactive and effective GMP and sanitation program. But what are the critical components of such a program? What resources do you have to establish and implement the program? Finally, how do you validate the effectiveness of the program and work toward continuous improvement?

Our upcoming GMP/Sanitation Workshop on June 22-23 will guide you through each of these steps and more, providing you the rules, best practices, support and resources to produce non-violative product in sanitary conditions. Working together, we can continue to reduce the incidence of foodborne illness around the world.

Should you have any questions, please contact us at info@aibinternational.com.