The Role of Personal Hygiene Practices in Food Safety [Free Download]

Regardless of an employee’s role in the food manufacturing process, they have an outsize impact on the overall safety and quality of the food they’re handling, packaging, or storing.During working hours, it’s critical employees direct their focus to upholding food industry hygiene standards. Any deviation from protocol could put public health at risk.

All personnel working in direct contact with food, food-contact surfaces, and food-packaging materials need to know what food industry hygiene standards are, and how to adhere to them. This requires both robust training and a food safety culture that continuously reinforces hygiene adherence.

Good Hygiene Practices in the Food Industry

As outlined in the AIB International Consolidated Standards for Inspections, current Good Manufacturing Practices (GMPs) require operations to provide suitable facilities to personnel for routine handwashing so they may remove contamination from hands. Sanitary conditions must also be maintained in all employee washrooms, showers, and locker rooms.

While on duty, all personnel working in direct contact with food, food-contact surfaces, and food-packaging materials must adhere to hygiene practices to prevent allergen cross-contact and food cross-contamination issues.

It is expected that all personnel wash their hands before beginning work, and after eating, drinking, smoking, using the restroom, or otherwise soiling their hands.

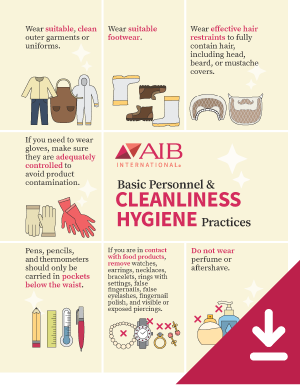

Some of the basic personnel hygiene and sanitation best practices in the food industry include:

- Wear suitable, clean garments or uniforms.

- Wear suitable footwear.

- Wear effective hair restraints to fully contain hair, including hair nets, headbands, caps, beard or mustache covers, or other effective hair restraints.

- If gloves are needed, make sure they are adequately controlled to avoid product contamination.

- Personnel in contact with food products need to remove watches, earrings, necklaces, bracelets, rings with settings, false fingernails, false eyelashes, fingernail polish, and visible or exposed piercings.

- Personnel should not wear perfume or aftershave.

- Pens, pencils, and thermometers should only be carried in pockets below the waist in the production area.

Details Make the Difference With Food Industry Hygiene Compliance

Plants should include locker rooms or equivalent changing facilities for employees, visitors, and contractors for use before entering the food processing area. There should be enough space to store work clothes and shoes separately from outdoor clothing, shoes, and personal items. Whenever possible, changing facilities must be located near or with direct access to production, packaging, and storage areas. Where protective clothing is required, management must ensure it’s always available and laundered or cleaned in a controlled environment.

Personnel Hygiene Requirements Around the World

Personal hygiene requirements in the food and beverage industry are regulated in most countries around the world, with regulations calling for very specific requirements or simply setting expectations about how employees should behave.

- In the United States, the Code of Regulations Title 21, Subpart B, Part 117.10 lists all the reasonable measures and precautions that food manufacturers need to meet regarding personnel.

- In Europe, Anexx II of the Regulation (EC) No 852/2004 of the European Parliament and the Council of 29 April 2004 on the hygiene of foodstuffs provides the European Union with basic guidelines regarding personal hygiene.

- In Australia, Standard 3.2.2. Food Safety Practices and General Requirements reinforces the importance of good personal hygiene practices to ensure the production of safe food.

- In India, you can find the personal hygiene requirements for food businesses in the Food Safety Standards (Licensing and Registration of Businesses) Regulation 2011, Section 10, part 10.2.

- And in Mexico, the standard NOM-251-SSA1-2009 specifies the personal hygiene practices expected in all food manufacturing facilities.

Even though some of these regulations are more specific than others, the objective remains the same: to ensure the safety of food.

Extra Support for Maintaining Sanitation and Hygiene in the Food Industry

Upholding food industry hygiene standards requires deep knowledge and constant vigilance. These standards can be difficult for even exemplary employees to always adhere to perfectly, let alone an entire team of people and the company culture they share. Understandably, keeping your personnel in compliance with regulations can sometimes require outside help.

AIB International supports worker training at every level, from on-the-ground frontline staff to executives and management. Our robust training programs update all employees with knowledge about the latest regulatory standards and best practices, as well as provide practical, hands-on training about implementing what they learn in their shifts. Want help building a culture that upholds food industry hygiene standards? Learn more in our Personnel Practices online training.

![The Role of Personal Hygiene Practices in Food Safety [Free Download]](https://blog.aibinternational.com/hubfs/handwashing%20blog.jpg)