Why Food Safety Should Be at the Center of Your Facility Remodel or Redesign

If your business is thriving, you may find that your current facilities are struggling to meet increased production needs — overall, a good problem to have. To address this issue, you may be planning a remodel, expansion, or redesign of your space. While this presents exciting business opportunities, it also poses new challenges for preserving (or even improving) your facility's food safety protocols.

In any food processing plant redesign, food safety comes first. The compatibility of your design with your facility's food safety efforts will not only determine your compliance with regulatory standards — it will also influence production capacity and efficiency.

Before you commit to a design plan, it's vital to proactively consider the role that your layout, materials, and equipment will play in ensuring food safety and protecting your food supply.

Sanitary Design and Its Role in Food Safety

Building a new facility (or expanding your current one) with food safety in mind requires applying sanitary design principles. But what is sanitary design, and how does it impact food safety efforts?

Sanitary design is a facility design process centered around cleanability, contamination resistance, and overall hygiene. This design philosophy can help optimize food safety throughout your facility, increasing your odds of regulatory compliance by ensuring that your equipment and layout meet several key requirements:

-

Cleanability: Spaces and equipment should allow for easy cleaning, debris removal, and sanitization to meet food safety standards.

-

Accessibility: Surfaces and parts should be easy to reach for cleaning, maintenance, and inspection, reducing barriers to compliance.

-

Compatibility: Materials used in your building and equipment should withstand regular cleaning and processing, as well as resist corrosion, absorption, and toxicity.

Implementing these sanitary design principles during your remodel is foundational to preventing contamination and facility-related food safety incidents, and ultimately setting your operation up for success.

Benefits of Sanitary Facility Design

Implementing sanitary facility design in your remodel, redesign, or expansion is essential to optimizing your food safety compliance — as well as enabling operational efficiency. By applying sanitary design principles, you can tap into a few key benefits that drive food safety:

-

Reduced cross-contamination and cross-contact: Equipment made from durable, easy-to-clean materials can reduce the spread of allergens, physical contaminants, and bacteria. Additionally, properly laid-out facilities reduce the risk of allergens contaminating non-allergen-containing food products, a crucial measure to prevent cross-contact.

-

Better execution of food safety strategies: Thanks to the accessibility and cleanability principles of sanitary design, your team can more easily follow and execute your food safety plan — without the hindrance of cumbersome equipment or inefficient floor layouts.

-

Minimized pathogen growth: Equipment and facility features like proper drainage and sloped surfaces reduce the potential for liquids to pool and harbor harmful bacteria.

-

Optimized quality and shelf life: Sanitary design protects your products’ integrity during storage and maximizes potential shelf life by minimizing spoilage.

-

Increased operational efficiency: Applying sanitary design principles across your food processing plant can cut down on cleaning time and costs, minimizing downtime and improving your team’s productivity — while ensuring food safety.

But before you can tap into these advantages, there are several factors to consider as you design your updated facility.

Key Food Safety Considerations for Your Remodel or Redesign

To achieve a safe food manufacturing environment, you must be proactive about how your facility enables food safety and minimizes risk. Account for every detail from the ground up to ensure your product is as safe as possible — whether it be the layout of your operations or the materials you use to build.

Equipment design and use

From the materials it’s made from to how it’s assembled, your equipment design can play a key role in reducing the spread and growth of contaminants during processing. For example, machinery should be:

-

Non-porous

-

Smooth

-

Free of cracks or crevices

-

Corrosion-resistant and non-reactive

-

Durable

-

Low-maintenance

The machinery you purchase should also be made from easy-to-clean materials that can stand up to the daily wear-and-tear of your sanitation protocols, such as:

-

Stainless steel

-

Plastic

-

Titanium

-

Aluminum

But starting with the right equipment is only part of the journey toward running a safe facility. Your team must also know how to best use, clean, and maintain this equipment to ensure your food safety protocols are executed as intended.

Zoning

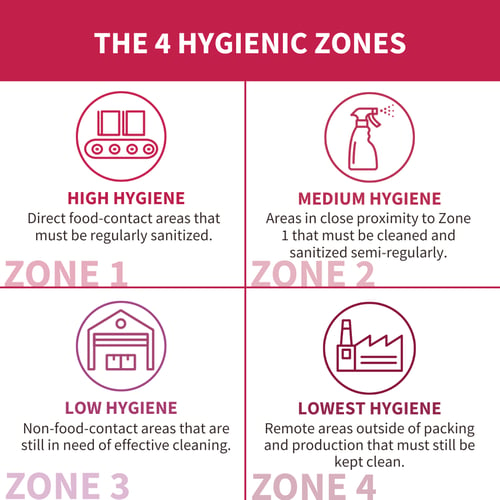

In food manufacturing, zoning is the strategic division of your food processing plant based on contamination risk. Hygienic zoning, in particular, is a food safety system that divides food processing plants into distinct zones, prioritizing cleaning and sanitation efforts. It also encompasses preventive measures to reduce the chances of contamination.

This system is an effective way to not only enhance your facility's food safety, but also meet the hygiene requirements laid out in the Food Safety Modernization Act (FSMA). While the FSMA doesn’t require this particular zoning method, it’s an easy way to implement general preventive and sanitation controls that are required.

This system breaks your facility design into four key zones:

-

Zone 1 - High hygiene: Direct food-contact surfaces such as conveyor belts, tabletops where product is handled, and more, that must be regularly sanitized to avoid contamination.

-

Zone 2 - Medium hygiene: Areas that are not in direct contact with food products, but are in close proximity or adjacent to them, that must be cleaned and sanitized semi-regularly to avoid contamination. This could include outer parts of machines, framework, walkways, and more.

-

Zone 3 - Low hygiene: Non-food contact areas, like restrooms or storage areas, that should be cleaned effectively but are not under the same scrutiny as zones 1 and 2.

-

Zone 4 - Lowest hygiene: Remote areas outside the packing and production areas, such as hallways, offices, and more, that often aren’t considered a threat for potential contamination but should still be kept clean.

This system allows your team prioritize cleaning efforts to minimize potential contamination risks and can even inform your facility layout

Building materials

Your facility’s construction materials also play a role in reducing food safety incidents. Materials must be durable to prevent physical contaminants from entering products and withstand the rigors of regular cleaning and sanitation practices — including physical and chemical abrasion.

Every aspect of your facility's construction must be considered when choosing durable materials, even including areas that may not come into direct contact with your food products, such as:

-

Floors

-

Wall finishes

-

Exposed ceiling structures

-

Light fixtures

These surfaces can present opportunities for bacteria to grow and spread if not designed with food safety in mind, and can also create bottlenecks for cleaning.

Ensuring the durability and cleanability of each surface in your facility meets the requirements of sanitary design principles allows you to create a space that makes it easy to maintain food safety compliance while operating efficiently.

Floor plan

One of the most important parts of your facility redesign is the layout of your floor plan. How products or employees move through your facility and where your machines are located will impact how likely allergens or contaminants are to spread — as well as how efficiently your plant operates.

Machines that process products containing allergens, for example, should ideally be placed in a separate area to minimize cross-contact. Employees handling these products should also be able to transport them without potentially exposing these allergens to other products. Separating raw materials is similarly essential to reduce the potential contamination of ready-to-eat foods.

Consider physical contamination from overhead as well. Placing elevated or second-floor walkways directly above production areas can pose a risk of objects and debris falling onto the production line.

Maintaining the Effectiveness of Your Facility's Design

From your equipment to the layout of your production line, your facility's design sets the stage for how safely and efficiently your team can keep up with your newfound demand.

But facility design isn’t a one-and-done task; food safety best practices are ever-evolving, as is your operation. Once you have a design that maximizes your food safety compliance, you need to ensure it doesn't fall out of repair. Learning best maintenance practices can help improve the longevity of your facility's food safety compliance.

To learn more about how your team — from your front line to your C-Suite — can proactively maintain your food processing equipment, sign up for AIB International's Maintenance Engineering Online course. This online training will empower any member of your team to help maintain equipment integrity and positively impact on your food safety efforts.